Home Pages

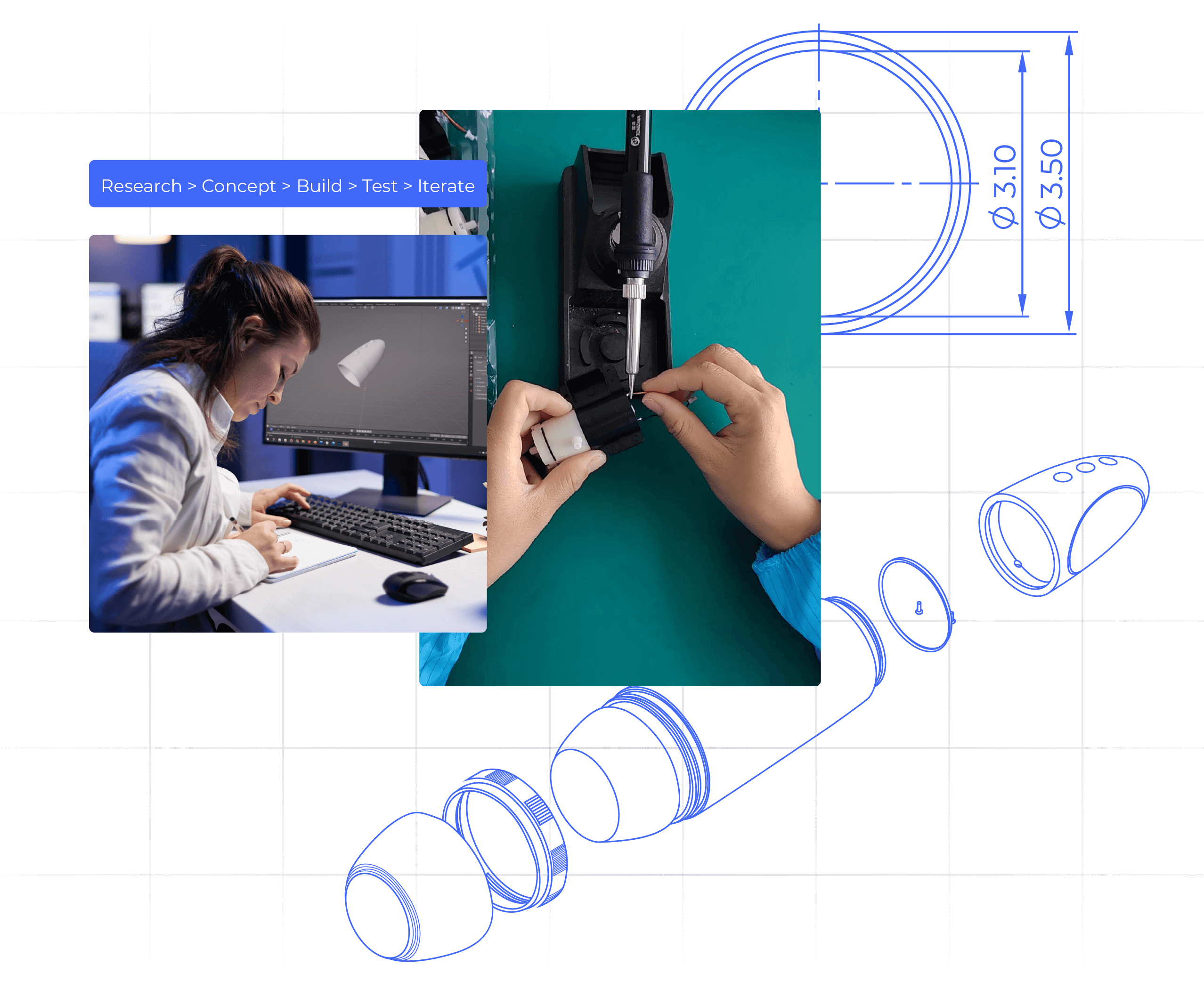

How We Design and Manufacture Products at LYNK

Mainstream Product

Mainstream use means people demand effective products from brands they can trust. We’re proud to have earned that trust – but it hasn’t happened by accident. Every product you see carrying the Lynk name has been through a rigorous design, development, testing, and feedback process.

It’s our way of ensuring your hard-earned dollars are invested in products that will bring new levels of pleasure and satisfaction to your life. Here, you’ll see the product design and development process we use here at Lynk Pleasure – including fresh ways of thinking about men’s products that have helped to reshape our industry.

Understanding your needs and industry shortcomings

The Problem

Traditionally, men have been an afterthought for most sex toy manufacturers. If you were lucky, a sex toy website would have a few token products – but the real focus was on women’s toys. This approach created an ongoing problem – men didn’t buy these second-rate products, and manufacturers had no incentive to design and develop products that genuinely catered to men.

Breaking this loop was one of the core ideas behind the creation of Lynk. Excellent products were very hard to find – and when they could be found, they only catered to a small number of tastes and needs. Premium men’s products did exist – but a big price ticket rarely meant you got a great toy. Instead, you’d get a basic toy made from premium materials.

We knew it was time to approach men’s sex toys in a revolutionary new way.

Innovative Design

Premium materials and manufacturing standards have always been important to the Lynk team – but since day one, we have understood that men’s performance products need to be designed with a deep understanding of what users want and need.

Every pump, sleeve, ring, massager, and toy you see in our store is created following extensive research. We set out to discover what men really wanted from sex toys and how we could use real anatomical science to make sure we delivered exceptional products.

Careful Planning and Project Creation

Design and Materials

Understanding the needs and physiology of a person is a great theory to work from – but a huge amount of work is done by our product development teams to ensure this research is put to the best possible use. When we have identified a need, we connect it to a series of design features. To ensure these features deliver what our potential users are looking for, we gather highly-experienced teams of people to be absolutely sure that we’re developing products that meet our potential customers’ needs. Of course, a design concept will only ever be as good as the materials we use to bring it to life. The right materials play a huge role in usability. By considering materials in detail, we can factor in everything from comfort and usability to hygiene and durability.

Our panel of design and materials experts are involved in every step – bringing years of experience to every step of the development process. Their knowledge gives us insight into how different chosen materials respond to the human body and whether they will deliver the ultimate experience.

As any user will tell you, a well-thought-through design is nothing if it doesn’t translate into an exceptional hands-on experience.

Extensive Product Testing and Expert Review

Lynk's Commitment to Quality Assurance

This is why the next step in our product development process involves creating a series of prototypes. At Lynk, we take nothing for granted – despite having been in the industry for over a decade. We want to be 100% certain that every feature translates into real-life performance. To make sure we achieve this performance, we have a Quality Assurance team that puts together specific tests; designed to ensure every product meets the high standards we’ve become known for. When our products are tested, there’s no checkbox for “does this meet minimum standards?” – instead, development continues until we know we’re hitting the maximum levels of performance and satisfaction.

Hygiene Standards for High-Performance Products

Performance doesn’t just mean pleasure either. Hygiene is an essential part of everything we do. We want to know how easy our products are to clean, how clean they are after being washed by the average user, and how they react to a vast range of cleaning products. Cleanliness is a non-negotiable, so nothing goes beyond the prototype stage unless we’re sure it meets our industry-leading standards. Our testing process is focused on real people and extensive questionnaires that help us analyze every aspect of performance. We don’t just want to know what’s great about our products – we’re also extremely keen to identify any problems or pitfalls, so we can keep adjusting until we’ve got a product we’re proud to showcase as part of the Lynk brand.

Production Followed by Ongoing Feedback and Development

Our customer relations team actively seeks feedback and logs every piece of information that comes back – no matter how insignificant it might at first seem. All feedback is continually monitored with oversight from our head of customer relations. We realize that everybody is different and that it would be impossible to create a product that caters to 100% potential users, but that doesn’t stop us from striving for the best final design. As customer feedback is collated, we look for trends – and if we need to address any element of our design, we will.

Most companies have a significant gap between product development and customer relationship teams – but we do things differently at Lynk. Our Head of Customer Relations is always part of our product development phases – meaning our users’ tastes, wishes, experiences, and desires are at the heart of every product and every development step.